|

Feed wheels (recommended for specific applications)

|

|

MSF 3

MEMMINGER-IRO

|

Storage feed wheel

|

- Constant yarn tension

- Steplessly adjustable yarn tension

- Increase of the machine effectiveness

- Reduction of the errors in the fabric

- Thread control through non-contact sensors on the coiling

- Thread separation of 1 mm avoids that the yarn layers hook together when pulling-off.

|

|

EFS 820

MEMMINGER-IRO

|

Electronic storage feed wheel

|

- For all elastic yarns on flat knitting machines

- Yarn tension adjusting, electronic feed wheel with yarn sensor

- The yarn sensor provides for constant tension over the entire yarn speed range

- Finer appearance to fabric: The Elastane pulls the stitches together, making the fabric gauge look finer

- Even knit structure, uniform appearance to fabric

- Softer handle to fabric, even with high-twist and hard yarns

- Collars and cuffs keep their shape

|

|

EFS 920

MEMMINGER-IRO

|

Electronic storage feed wheel

|

- Integrated yarn take-up system for elastic and non-elastic yarns

- With both directions exactly the same yarn tension

- Higher machine speeds

- Increased stability of the yarn tension by adjusting in the millisecond range.

- The large yarn tensioning path up to 600 mm covers the entire range of applications

- The individual devices can be variably grouped.

|

|

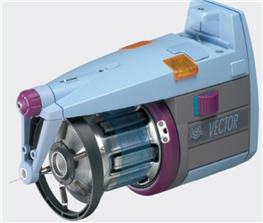

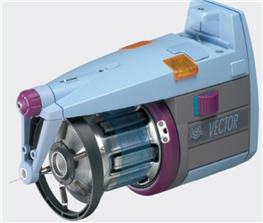

VECTOR

LGL Electronics

|

Storage feed wheel

|

- Constant yarn delivery

- Ideally suited for the use of different yarn thicknesses (556 dtex to 11 dtex)

- Automatic speed regulation according to the yarn quantity needed by the machine.

- Yarn storage control by a magnet sensor system.

- Stop function in case of yarn breakage or empty bobbins.

- Assembly of different brake units at the input and output

- Different assembly possibilities.

- Recording and display function referring the yarn consumption per case in real time (VECTOR XL).

- Electronic brake ATTIVO (optional). The user sets the desired tension at the output of the feeder, so that the system keeps functioning and avoids all tension variations caused by the yarn, the bobbin, etc.

|

|

BTSR

ULTRAFEEDER

|

Electronic storage feed wheel

|

- Programmable Yarn Tension

0.2 cN ÷ 100 cN - User Interface:

Selection of use cases (socks, hosiery, seamless, medical, knitting, Raschel, ...). - INC/DEC function:

Increasing and decreasing of the yarn tension step by step of 0.1 cN - LFA self learning:

- With automatic machine stop when exceeding the specified tolerance

(BTSR® patent). - MATRIX CONTROLLER required

- Target setting:

Specified target for the production by meters with the according automatic machine stop.

|