Step by Step to 'Pattern-7'

- A pattern project with one pattern and the desired settings is created.

- 1

- To draw select any desired drawing tool under the Drawing group.

- 2

- In the Pattern Colors tool window, select the desired pattern colors from the Yarn Colors color palette to draw the motif:

- Yarn Colors:

-

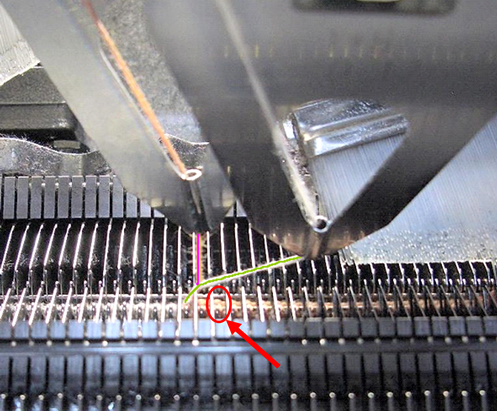

: The yarn carriers are not automatically placed on the yarn carrier rails.

: The yarn carriers are not automatically placed on the yarn carrier rails.

The yarn carrier home position is determined in the Technical Processing.

- 3

- In

Design Pattern draw the desired motif.

Design Pattern draw the desired motif.

|

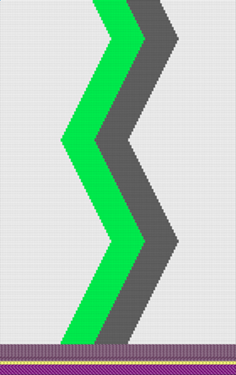

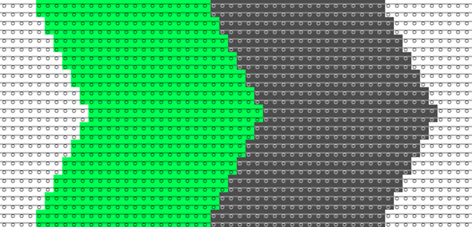

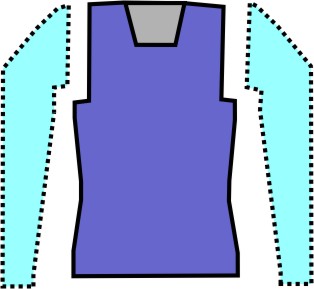

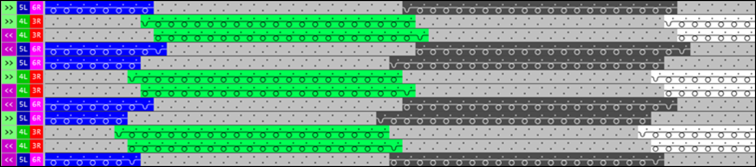

Example with 3 yarn colors without shape | |

|

|

Pattern neckline

|

|

| |

|

|

Notice:

|

- 4

- In the

Design Pattern adjust the motif accordingly, if desired.

Design Pattern adjust the motif accordingly, if desired. - 5

- To create a project-related lined shape, select the

Shapes tab in the tool window.

Shapes tab in the tool window. - 6

- Open the context menu with RMB and select Create New Shape of Size M....

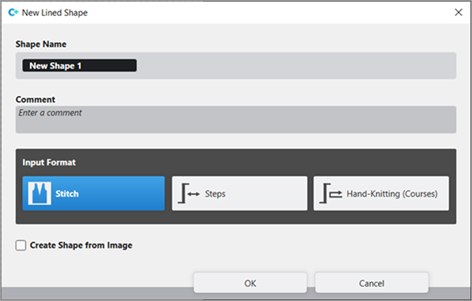

- The New Lined Shape tool window is opened.

- 7

- Make the desired entries:

- Shape Name: Any

- Input Format: Stitch

- 8

- Confirm with the OK key.

- The new lined shape (basic shape) is graphically displayed in the

Shapes tab and in a new document window

Shapes tab and in a new document window  as rectangle.

as rectangle.

: The default attributes will be used for the shape edges of the lined shape.

: The default attributes will be used for the shape edges of the lined shape.

Menu File -> Options -> Lined Shape -> Options for New Lined Shape

- 9

- To create a lined shape based on the displayed rectangle in the ribbon Shape Editing under Properties, click the

Line Table button.

Line Table button.

- or -

Use the graphic displayed in the document window.

document window.

: The method (table or graphic) to create a project-related lined shape is freely eligible, since the views are always updated simultaneously.

: The method (table or graphic) to create a project-related lined shape is freely eligible, since the views are always updated simultaneously.

- 10

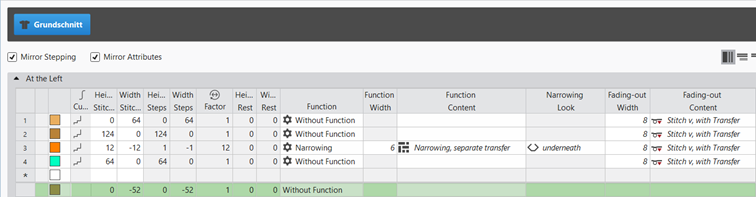

- Insert new shape lines in the table and enter the desired values for the basic shape.

- Standard attributes from configuration are assigned to those shape lines.

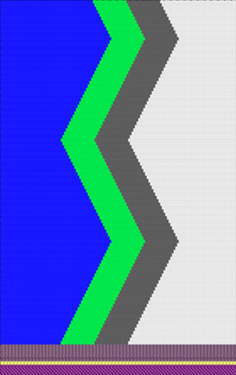

Example: Lined shape for Pattern-7

|

Basic Shape: Front without neckline |

|

|

Rules for creating a shape for the knitting mode SJ:

Example Front:

|

Shape Attributes |

Rules / possible settings |

|---|---|

|

Knitting Mode: |

Single Jersey |

|

Step width of widening |

1 needle (stitch) per knitting row |

|

Step height of widening |

As desired |

|

Quantity of rows without shape modification |

As desired |

|

Step width when narrowing |

1 - 3 needles (stitches) |

|

Step height when narrowing |

As desired |

|

Fading-out Width |

As desired |

|

Knitting mode for fading-out |

Front Stitch with Transfer |

|

Binding-off width: |

Stepping > 3 stitches |

|

Binding-off methods |

Binding-off, Structure, Single Jersey

|

- 11

- Allocate the desired attributes to the shape lines.

- 12

- In the Shapes tool window select the created shape with LMB.

- 13

- Open the context menu -> Position Shape -> select Pattern name.

- The shape is floating in the selected basic pattern.

- 14

- To position the shape, enable the

button of the document window.

button of the document window. - 15

- Carry out

Technical

Processing if necessary.

Technical

Processing if necessary. : After carrying out the

: After carrying out the  Technical

Processing you are able to view and weigh up the result of the automatic processing, if corrections / optimizations are necessary.

Technical

Processing you are able to view and weigh up the result of the automatic processing, if corrections / optimizations are necessary. - 16

- Back to the

Design Pattern to make pattern-related changes.

Design Pattern to make pattern-related changes. - 17

- Open the Yarn Carriers tool window for this purpose.

- 18

- In the Color Parameters table make the desired changes in the following groups, if necessary:

- Knitting-in and Out

- Intarsia Binding

- Border Processing

- 19

- If desired, make the desired presets in the following control columns:

- Stitch Length (NP)

- Main Take-down (WMF)

- Speed (MSEC)

- 20

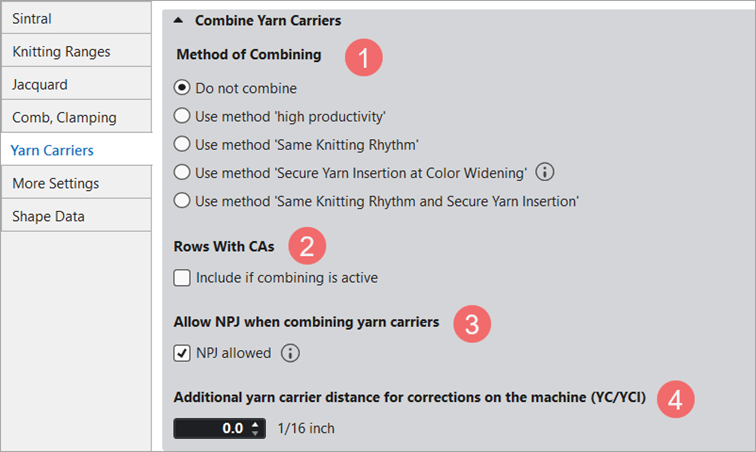

- If necessary, make the desired presets for combining yarn carriers in the More Settings tab of the Configuration dialog box.

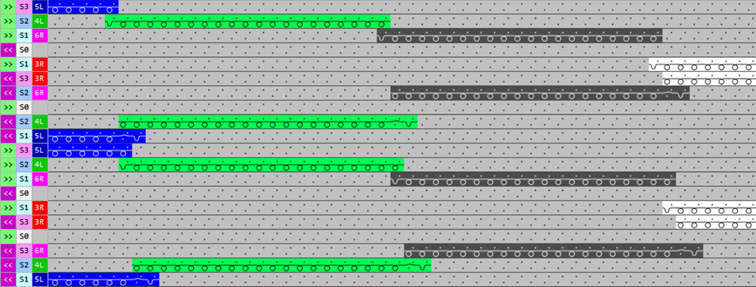

Several yarn carriers are combined in one system by the technical processing (knitting sequence) to optimize the production time.

:

:

The yarn carriers will be combined only if this is possible based on the color field distances.

The result is visible in the  Symbol View after the technical processing.

Symbol View after the technical processing.

Options in the Configuration dialog box

- 1

- In the ribbon select the

Configuration button.

Configuration button. - The dialog box appears.

- 2

- Select the More Settings tab.

- 3

- Make the desired presettings for the Combine Yarn Carriers.

-

Yarn Insertion:

Secure Yarn Insertion at Color Widening is active (standard)

Secure Yarn Insertion at Color Widening is active (standard)

|

| ||||

|

1 |

Yarn Insertion | |||

|

|

Do not combine (Default setting) | |||

|

No automatic combining of the yarn carriers.

| ||||

|

|

Combining with high productivity | |||

|

Automatic combining of the yarn carriers, where the result cannot be influenced.

| ||||

|

|

Secure Yarn Insertion at Color Widening | |||

|

Automatic, uniform combining of the yarn carriers with an optimized knitting process for secure yarn insertion with the tuck binding.

| ||||

|

2 |

Allow NPJ when combining yarn carriers | |||

|

|

NPJ allowed (default setting)

Result:

| |||

|

|

NPJ allowed is disabled

Result:

| |||

|

3 |

Additional yarn carrier distance for corrections on the machine (YC/YCI) | |||

|

|

Adjust the safety distance in order to make corrections on the machine (YC/YCI in the setup).

| |||

- 21

- Start the

Technical

Processing.

Technical

Processing.

With the button, show Symbol view after technical processing.

button, show Symbol view after technical processing. - The yarn carriers are automatically combined after the set specifications and the Intarsia rules (constructive facts of the Intarsia yarn carriers on the machine).

Setting in the Configuration dialog box

- 4

- In the ribbon select the

Configuration button.

Configuration button. - The dialog box appears.

- 5

- Select the More Settings tab.

- 6

- Make the desired presettings for the Combine Yarn Carriers:

-

Yarn Insertion:

Do not combine is enabled

Do not combine is enabled

- 7

- Start the

Technical

Processing.

Technical

Processing.

- The yarn carriers will not be combined automatically. This corresponds to a nice, uniform Intarsia knitting process with a high machine run time.

- 22

- Generate

Sintral.

Sintral. - 23

- Start the

Sintral Check.

Sintral Check. - 24

-

Extract the knitting program.

Extract the knitting program. - A program for the knitting machine will be created: CMS530.Pattern-7.zip.

- 25

- Load knitting program into the machine.

: The extracted file CMS530.Pattern-7.zip can be loaded onto the machine with an USB stick or via Ethernet.

: The extracted file CMS530.Pattern-7.zip can be loaded onto the machine with an USB stick or via Ethernet.