Step by Step to 'Pattern-5'

- A pattern project with one pattern and the desired settings is created.

- 1

- To draw select any desired drawing tool under the 绘图 group.

- 2

- In the 花型颜色 tool window, select the desired pattern colors from the 纱线颜色 color palette to draw the motif:

- 3

- Draw the desired motif in the

设计花型.

设计花型.

- 4

- Draw additional yarn colors for the inverse plating area in the design pattern.

: The corresponding yarn colors for creating the plating colors must be available for each inverse plating area.

: The corresponding yarn colors for creating the plating colors must be available for each inverse plating area.

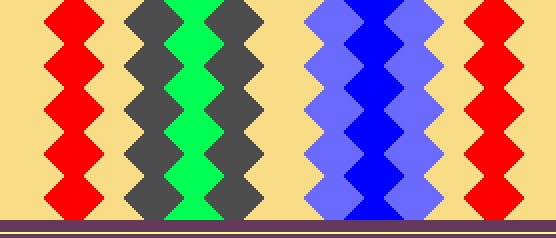

- Area 1 (left): Yarn color #2 and yarn color #4

- Area 2 (right): Yarn color #3 and yarn color #10

- 5

- Open the 添纱颜色 dialog box with

in the 花型颜色 tool window.

in the 花型颜色 tool window. - 6

- In the tool window, enter the yarn colors used for area 1 in row P1 under columns A and B.

- 7

- Paste the used yarn colors in exchanged order under P2.

: The exchange of yarn colors in the 添纱颜色 tab determines the change (inverse plating) of the yarn carriers.

: The exchange of yarn colors in the 添纱颜色 tab determines the change (inverse plating) of the yarn carriers.

- 8

- Use the same procedure with the corresponding yarn colors to create the plating colors P3 and P4 for area 2.

- 9

- Open the Plating Offset (YPI) table.

- The 添纱偏移 (YPI) tab of the Pattern Parameters dialog box appears.

- 10

- Select YPI index (1) and assign it to both yarn colors in column A for P1 and P2.

- 11

- Select YPI index (2) and assign it to both yarn colors in column B for P1 and P2.

- 12

- Enter the settings for the selected YPI indices in the table.

- 13

- Create two new entries for the use with the plating colors P3 and P4 in the 用户 table of the 添纱偏移 (YPI) tab.

- 14

- Use the same procedure to allocate the new YPI indices to the plating colors P3 and P4.

|

|

|

|

|

Inverse plating (with system change) For the so called Inverse Plating (with system change), a different plating color is required for each color change. |

- 15

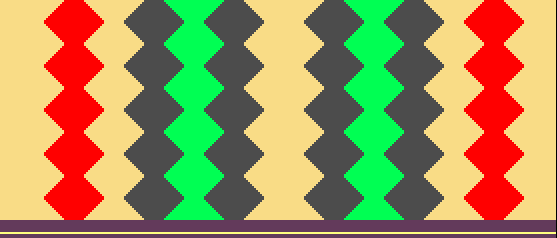

- Draw the plating colors P1 + P2 into area 1 (left) of the design pattern.

- 16

- Draw the plating colors P3 + P4 into area 2 (right) of the design pattern.

- 17

- If desired, define a cycle for length control in the

control column.

control column. - 18

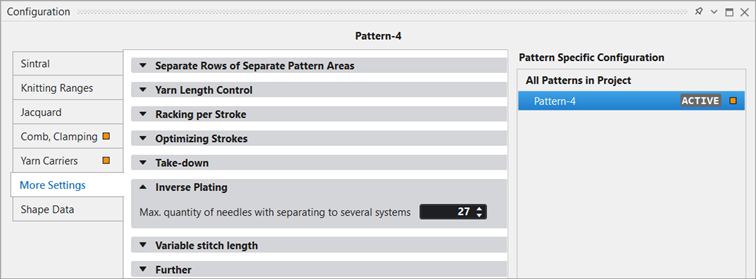

- If desired, modify the value under 反向添纱 in the 更多设置 tab of Configuration:

|

| |

|

|

Maximum quantity of needles with separating knitting rows to several systems.

|

- 19

- Make the desired settings in the

导纱器 tool window.

导纱器 tool window.

- 编织带入

- 编织带出

- 边界处理 etc.

- 20

- Make the desired setting at 合并导纱器 in the 更多设置 tab of the 配置 dialog box.

- Do not combine: Long run time

- Combining with high productivity (default): Short run time due to optimized knitting sequence

- Same Knitting Rhythm : Average run time due to constant knitting sequence

- 在颜色加宽部分固定纱线垫入: Short run time in compliance with the rules for safe yarn insertion (tuck binding at the yarn field border).

- Same Knitting Rhythm and Secure Yarn Insertion : Average run time in compliance with the rules for safe yarn insertion.

- 21

- Enable the 'split' system function in the machine attributes if desired.

- 22

- Carry out all the steps of processing.

: The extracted file ADF530-32W.Pattern-5.zip can be loaded onto the machine with an USB stick or via Ethernet.

: The extracted file ADF530-32W.Pattern-5.zip can be loaded onto the machine with an USB stick or via Ethernet.