Step by Step to Pattern-2

- A pattern project with one pattern and the desired settings is created.

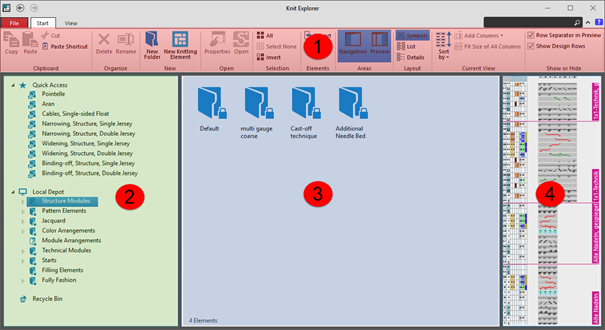

- 1

- Select an existing Aran pattern element in Knit Explorer to draw.

- or -

Generate a private Aran diamond as a pattern element.

- Selection of the needed Aran structure modules via:

-

Knit Explorer

Knit Explorer -

Quick Access

Quick Access : The desired folder has to be added in

: The desired folder has to be added in  Knit Explorer to the folder

Knit Explorer to the folder  Quick Access.

Quick Access.

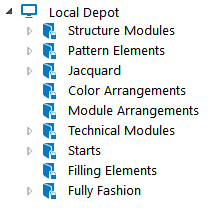

Knit Explorer

Knit Explorer

Knit Explorer

- Managing all STOLL knitting elements

- Pattern Elements

- All types of knitting elements

-

STOLL knitting elements are write protected

STOLL knitting elements are write protected - Managing self created pattern elements and knitting elements

|

| |||

|

1 |

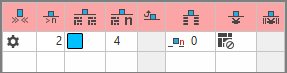

Ribbon |

File |

|

|

Start |

Functions for working in the | ||

|

View |

Possible settings for the Knit Explorer view | ||

|

2 |

Navigation Pane |

Quick Access |

Managing linked directories for a faster access |

|

Knitting Element Depot |

Managing all knitting elements / modules

| ||

|

3 |

Display of the content of a selected folder | ||

|

4 |

Preview of a selected knitting element / module | ||

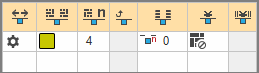

Marking of directories

-

Directory without property -

Directory without content -

Write-protected directory -

STOLL knitting elements are write protected

STOLL knitting elements are write protected -

Linked directory

Managing the Knitting Elements and Different Types of Knitting Elements

Managing the knitting elements in the  Knit Explorer

Knit Explorer

You will find the different types of knitting elements in the following directories:

-

This write-protected directories contains all the knitting elements from STOLL with their corresponding properties for each type of knitting element. - For a better structuring there are sub-directories assigned to the directories.

Types of knitting elements

- Pattern Elements

- Structure Module

- All structures with / without transfer rows

- Knitting element with connecting points

- Color Arrangement

- Module Arrangement

- Jacquard Module

- Technical Module

- Technical Design Module

- Narrowing Module

- Multi-step Narrowing Module

- Widening Module

- Multi-step Widening Module

- Binding-off Module

- Start

- 2

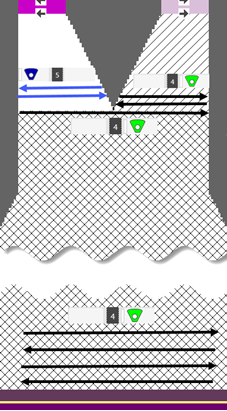

- Drawing of an Aran diamond with the drawing tools.

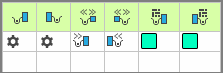

- Select group Modify, function

Multi-Copy.

Multi-Copy. : For easier, faster handling of the drawing tools, open the pop-up window with CTRL + Space bar.

: For easier, faster handling of the drawing tools, open the pop-up window with CTRL + Space bar.

- 3

- Filling of the interior of the Aran diamond with Pattern element / Structure module Moss Stitch with the following drawing tools and settings:

-

Magic Wand with corresponding settings in the group Fill :

Magic Wand with corresponding settings in the group Fill : -

Free Border

Free Border -

Exact to Border

Exact to Border -

Cover Border

Cover Border -

Fill Line

Fill Line

: The result when filling the Aran diamond depends on whether a pattern element or a structure module is used.

: The result when filling the Aran diamond depends on whether a pattern element or a structure module is used.

The use of a pattern element is recommended.

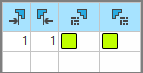

- 4

- Select the created Aran diamond.

- 5

- Press the keys CTRL + C.

- A temporary pattern element is assigned to the cursor.

- 6

- Draw basic pattern with the temporary pattern element.

- Create the selection as a temporary pattern element with CTRL + C.

: Pattern element is not saved and can be deleted from the cursor with the ESC button.

: Pattern element is not saved and can be deleted from the cursor with the ESC button. - Context menu -> Selection

-> Create Pattern Element...

: Pattern element will be saved as

: Pattern element will be saved as  Pattern Elements and with the project.

Pattern Elements and with the project. - Context menu -> Selection

-> Create Structure Module...

: Structure module will be saved as

: Structure module will be saved as  Modules and with the project.

Modules and with the project.

: Attention:

: Attention:

The behavior of the pattern element and module is different when working with shapes.

Recommendation:

Create the basic pattern only with pattern elements when working with shapes.

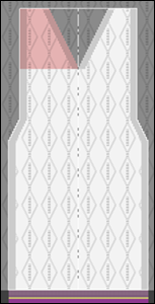

- 7

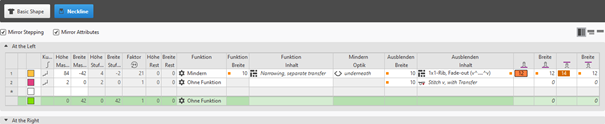

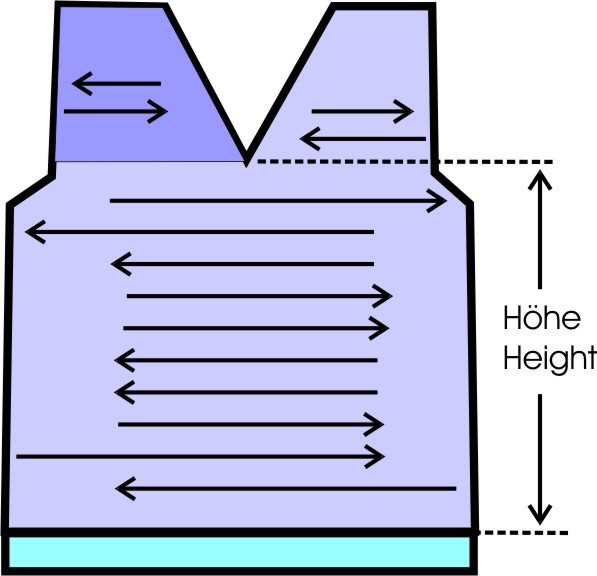

- Import and position the existing shape Front with V-neck.

: If the basic pattern is too small for the positioning of the shape, then the size of the basic pattern will be automatically adjusted to the size of the shape.

: If the basic pattern is too small for the positioning of the shape, then the size of the basic pattern will be automatically adjusted to the size of the shape.

: This adjustment always takes place with Front Stitch with Transfer .

: This adjustment always takes place with Front Stitch with Transfer .

- 8

- Open the shape with the

Line Table button.

Line Table button. - 9

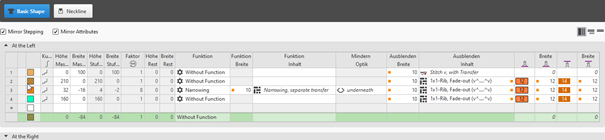

- Make the desired changes in the basic shape and neckline:

: These changes are directly visible in the document window

: These changes are directly visible in the document window  Design Pattern with positioned shape.

Design Pattern with positioned shape.

Narrowing:

- Function width

- 10 needles (stitches)

Fade-out:

- Fade-out width:

- 10 needles (stitches)

- Fade-out content:

- Shape edges in the basic shape: Knitting Element 1x1-Rib, Fade-out (v^....^v)

- Shape edges neckline. Knitting Element 1x1-Rib, Fade-out (v^....^v)

|

|

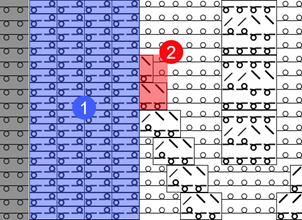

1 |

After cutting out the shape, the fading-out is inserted, where knitting elements are 'cut-into'. |

|

2 |

Cut into knitting elements are displayed.

| |

|

| ||

|

|

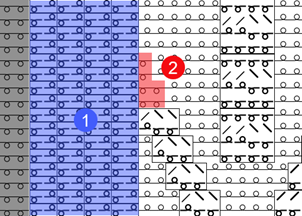

1 |

After cutting out the shape, the fading-out is inserted, where knitting elements are 'cut-into'. |

|

2 |

Cut into knitting elements are not displayed and are replaced by default with Front Stitch with Transfer.

| |

Power Tension Setting (NPJ) at the shape edge:

-

+

+  :

:

Allocation of the desired stitch length indexes for stitch length at the front / rear -

Width

+ Width

+ Width  :

:

Quantity of stitches for PTS (NPJ): 12 needles (stitches)

: Power Tension Setting (NPJ) is needed at the shape edge, to adjust the quality of the stitch lengths between the different structures Aran diamond and the 1x1 Rib at the shape edge.

: Power Tension Setting (NPJ) is needed at the shape edge, to adjust the quality of the stitch lengths between the different structures Aran diamond and the 1x1 Rib at the shape edge.

In the document window  Design Pattern switch the view to

Design Pattern switch the view to  Stitch Length at Front and Rear in Needle Area.

Stitch Length at Front and Rear in Needle Area.

- Shape generation in the current pattern project

- Tab Shapes -> Context menu Create New Shape of Size M...

- Shape generation with

New Lined Shape Project

New Lined Shape Project

|

Basic Shape |

|

|

|

|

|

Neckline |

|

|

|

|

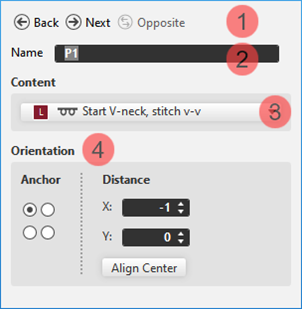

Displaying and changing marking point properties:

- In the

document window

document window - Position the cursor on a marking point in the displayed graphic -> open the context menu with RMB and select ->

Marking Point Properties and make the desired entries in the tool window.

Marking Point Properties and make the desired entries in the tool window. - With the

Marking Point Properties button in the ribbon, open the tool window and make the desired entries.

Marking Point Properties button in the ribbon, open the tool window and make the desired entries.

|

|

1 |

Buttons for switching between the created marking points | |

|

2 |

Name of the selected marking point

| ||

|

3 |

Used knitting element as marking | ||

|

4 |

Positioning of the knitting element at the marking point | ||

|

Anchor |

Corresponds to the reference point in a knitting element

| ||

|

Distance |

Offset in x direction and y direction for positioning the assigned knitting element regarding the marking point depending on the set anchor point | ||

|

Align Center |

Centers the assigned knitting element at the anchor point | ||

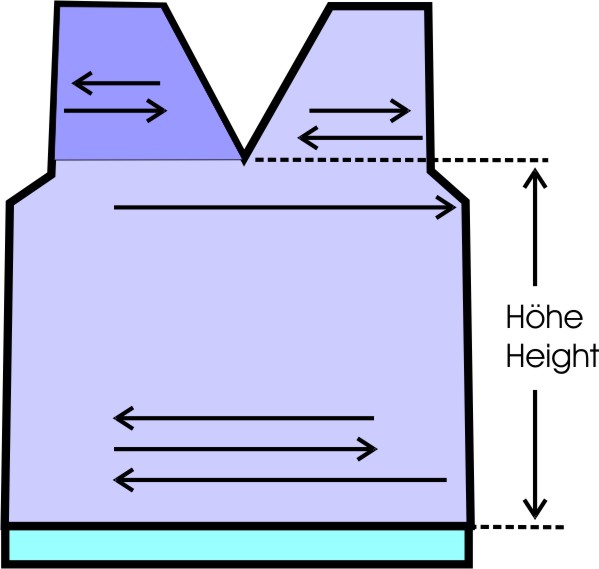

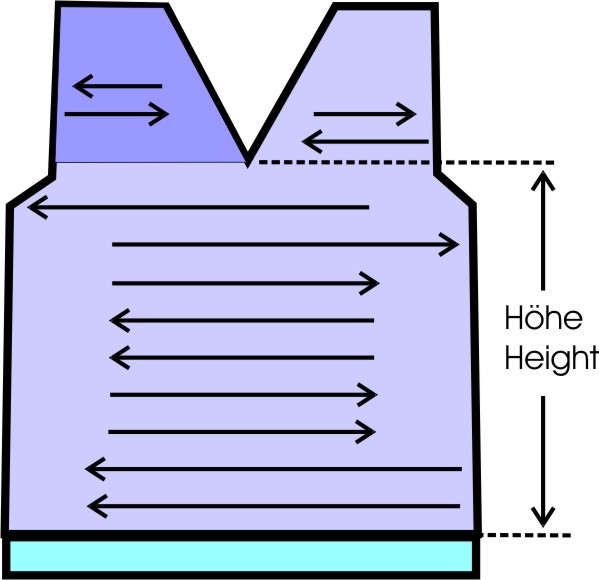

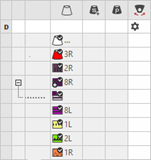

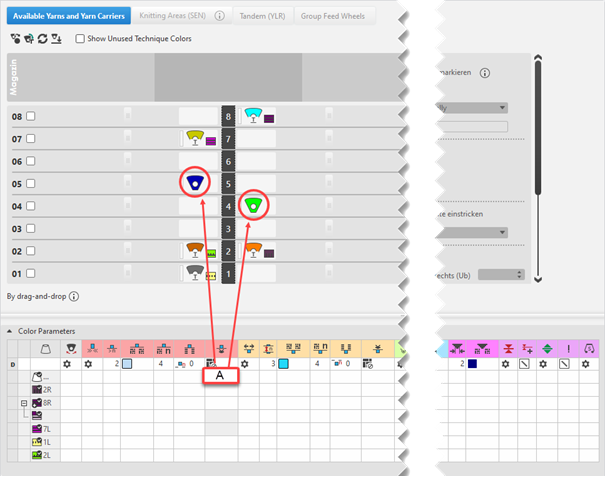

Quantity of yarn carriers for shapes with neckline:

The row number after the start up to the beginning of the neck has to be aligned to the number of yarn carriers in use to achieve a correct knitting sequence.

|

Graphic presentation |

Quantity of yarn carriers up to neckline |

Height up to neckline |

|---|---|---|

|

|

One yarn carrier |

Even-numbered |

|

|

Two yarn carriers in the same home position |

odd |

|

|

Two yarn carriers in different home position |

Even-numbered |

|

| ||

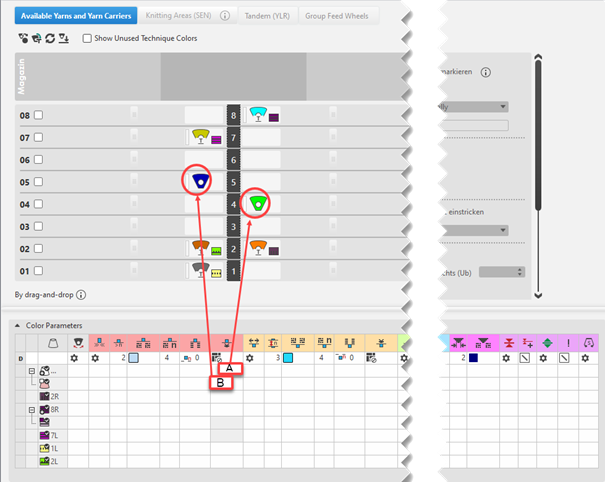

- 10

- Working in the dialog box

Yarn Carriers ->

Yarn Carriers ->  Show Yarn Carriers

Show Yarn Carriers

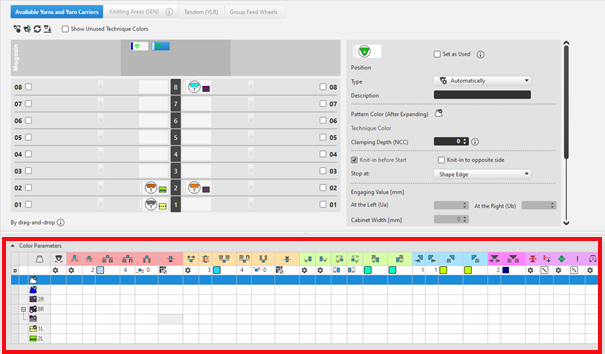

- Available Yarns and Yarn Carriers Tab

- Combine Yarn Carriers

- If desired, allocate the yarn carriers to the yarn carrier rails manually

- Color Parameters Table

- Allocate the Float, Lock, Fabric selvedge module as attribute to the yarn carrier of the left shoulder

Open the Yarn Carrier document window:

: The motive is created in the

: The motive is created in the  Design Pattern.

Design Pattern.

- Click the

Yarn Carriers button under Preview in the Start ribbon.

Yarn Carriers button under Preview in the Start ribbon. - The

document window is opened as view and the Yarn Carriers ribbon appears.

document window is opened as view and the Yarn Carriers ribbon appears. - Make the desired settings for the view of Yarn Carriers the status bar:

|

Yarn Carrier Colors as Background | ||

|

|

Switching the view between the different pattern colors

| |

|

| ||

|

Show Knitting-out | ||

|

|

inactive |

Knitting-out of the yarn carriers is not displayed in the graphic. |

|

Active |

Knitting-out of the yarn carriers is displayed in the graphic.

| |

Table Color Parameters

You can make the desired presettings for the colors used in the pattern (color areas) within the Color Parameters table.

Open the Color Parameters table:

- With the

Yarn Carriers button open the document window

Yarn Carriers button open the document window  (Pattern name) in the ribbon.

(Pattern name) in the ribbon. - Open the dialog box via

Show Yarn Carriers.

Show Yarn Carriers.

For each color in the pattern color tables used in the design pattern, a color area is created in the color parameter table.

This means that you can make presettings only once for this color area.

For pattern related, different changes of a color area sub-colors must be created. You have to draw them manually in the design pattern at the point to be changed.

Then, other specifications can be set in the color parameter table. - Make the desired presettings for the corresponding color:

- Knitting-in and out

- Change the starting direction of a color (yarn carrier)

- Knot or binding at start or end of a color

- Border Processing

- etc.

- Apply the modifications of the Color Parameter table to the pattern:

Edit group -> Apply

Apply

- or -

Edit group -> Apply and Close

Apply and Close

Functions of the Edit ribbon

|

|

Synchronize |

Applies the changes from the Design Pattern to the open Yarn Carrier View and synchronizes both views to the current state of the pattern. |

|

|

Apply |

Applies changes for yarn carriers to the Design Pattern. Other changes (e.g. of color parameters) will be applied at once. |

|

|

Apply and Close |

Applies changes for yarn carriers to the Design Pattern and closes the view. Other changes (e.g. of color parameters) will be applied at once. |

|

|

Cancel and Close |

Rejects modifications and closes the Yarn Carrier View. Close with Cancel and Close if you only opened the Yarn Carrier view for control. |

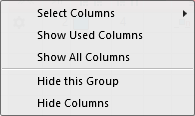

Adjust the display of the columns in the Color Parameters table:

- Move the cursor to the first row of the table header.

- Open the context menu with RMB.

|

| |

|

Select Columns |

Adding or closing the desired columns in the selection list. |

|

Show Used Columns |

Display of the columns used in the pattern |

|

Show All Columns |

Display all of the columns |

|

| |

|

Hide this Group |

Hide all columns allocated to a group (color coded) |

|

Hide this Column |

Hide the individual column at cursor position |

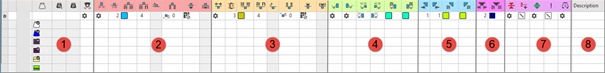

Structure and column headers of the Color Parameters table:

Group 1: General / Table header:

-

1st row:

All the symbols identifying the table columns -

2nd row D

Default settings for the respective column

Settings from the STOLL file - cannot be modified at the moment

Default settings are applied from a STOLL file and cannot be modified at the moment.

These are automatically applied to all colors without specifications.

|

| ||

|

Group 1: General | ||

|

| ||

|

1. Column |

Entry D for the definition of the 2nd row of the table | |

|

2. Column |

Display for available sub-colors | |

|

|

Color |

Display of all the colors used in a project

|

|

|

Yarn carrier knits a multiple system color |

Specifications with multi-system knitting |

|

|

Yarn carrier knits a plating color |

Specifications with plating |

|

|

Swivel |

Settings for the swivelling of intarsia yarn carriers or of autarkic yarn carriers |

|

|

Quantity of Rows for Knitting-out, SEN edge and clamping |

Specify the maximum distance between the color fields of the yarn carrier.

Clamp Yarn Carrier |

|

Group 2: Knitting-in | ||

|

| ||

|

|

Starting Direction |

Specification of the knitting direction for the first row of a color (color area) |

|

|

Quantity of columns without knitting-in |

Quantity of columns (wales) without knitting-in module |

|

|

Module for Knitting-in |

Specification of the knitting mode for knitting-in

|

|

|

Width of repetition for knitting-in |

Presetting of the module width in total for the knitting mode of feeding-in the yarn carrier

|

|

|

Moving Rows for Cast-off |

Column appears automatically if a module for knitting-in with casting-off is used |

|

|

Reihen-Offset für Einstricken / Knoten |

Knitting-in of the yarn carrier by x rows before the beginning of the color area

|

|

|

Knot or Binding at Start |

Presetting a module for knot / binding at start of a color area without knitting-in.

|

|

|

Column-offset for Knitting-in with a Knot |

Move the position of a knot (module) by x columns to the left or right.

|

The direction of knitting-in of a yarn carrier is always carried out from last position.

|

Group 3: Knitting-out | ||

|

| ||

|

|

Direction of the Knitting-out |

Preset of the direction for knitting-out of the yarn carrier at the end of a color area |

|

|

Module for Knitting-out |

Preset of the knitting mode (module) for knitting-out

|

|

|

Width of repetition for knitting-out |

Presetting of the module width in total for the knitting mode of feeding-in the yarn carrier

|

|

|

Moving Rows for Cast-off |

Column appears automatically if a module for knitting-out with casting-off is used |

|

|

Row-offset for Knitting-out |

Knitting-out of the yarn carrier by x rows after the end of the color area

|

|

|

Knot or Binding at End |

Presetting a module for knot / binding at end of a color area without knitting-out.

|

|

|

Column-offset for Knitting-out with a Knot |

Move the position of a knot (module) by x columns to the left or right.

|

|

Group 4 : Intarsia Binding | ||

|

| ||

|

|

Intarsia Binding at the Left |

Presetting of a binding or no binding at the left border of the color area |

|

|

Intarsia Binding at the Right |

Presetting of a binding or no binding at the right border of the color area |

|

|

Direction of the Intarsia Binding at the Left |

Specification for inserting the Binding module at the left border of the color area depending on the carriage direction

|

|

|

Direction of the Intarsia Binding at the Right |

Specification for inserting the module Binding at the right border of the color are depending on the carriage direction

|

|

|

Module for Intarsia Binding at the Left |

Presetting of the knitting mode for binding at the left border of the color area |

|

|

Module for Intarsia Binding at the Right |

Presetting of the knitting mode for binding at the right border of the color area |

|

Group 5: Border Processing | ||

|

| ||

|

|

Allowed stepping without border processing at the left |

Maximum number of needles when widening at the left border of the color area without automatic border processing.

|

|

|

Allowed stepping without border processing at the right |

Maximum number of needles when widening at the right border of the color area without automatic border processing.

|

|

|

Module for Border Processing at the Left |

Presetting of the knitting mode for the border processing (feeding) in case of large widenings (stepping) of the color area

|

|

|

Module for Border Processing at the Right |

Presetting of the knitting mode for the border processing (feeding) in case of large widenings (stepping) of the color area

|

|

Group 6: Multi Gauge | ||

|

| ||

|

|

Allowed Stepping of coarse multi gauge rows |

Allowed number of needles when widening at the left and right border of the color area without automatic border processing.

|

|

|

Module for border processing, transition mg coarse to mg fine |

Presetting of the knitting mode for the border processing (feeding) in case of large widenings (stepping) of the color area and as transition

|

|

Group 7: Miscellaneous | ||

|

| ||

|

|

Clamping |

Presetting for the yarn carrier, when it is to be clamped after knitting its color area. |

|

|

Delayed Clamping |

|

|

|

Open Clamp |

|

|

|

SEN Edge |

Specifications for positioning the yarn carrier during the knitting

|

|

|

System (independent of direction) |

Selection of a knitting system for the selected color area

|

|

Group 8 | ||

|

Description |

Note on the use of the entry.

You can enter a text here. | |

Standard behavior by the yarn carrier allocation

|

|

On the left side (shoulder) an additional yarn carrier is required for the yarn color #1 in shapes with neckline (shape element outside shape). It will be knitted-in from left by default at the start of the shoulder.

|

|

| |

|

| |

:

:

If there is the necessity to allocate other attributes to the yarn carrier of the left shoulder, there has to be another yarn color or a sub-color of the main color available in the table Color Parameters.

Creating Sub-colors within the Different Tables of Pattern Colors

Possible in the following tables:

- Yarn Colors

- Magazine Colors

- Technique Colors

- Yarn Carrier Colors

: You can create sub-colors in each of these tables in the same way.

: You can create sub-colors in each of these tables in the same way.

Creating Sub-colors:

: Be sure to create the sub-color for a main color used in the pattern only, as no additional yarn carrier should be added to the pattern.

: Be sure to create the sub-color for a main color used in the pattern only, as no additional yarn carrier should be added to the pattern.

With the help of the sub-color, you can allocate others attributes to a yarn carrier.

- Position the cursor to the

main color in use (e.g. yarn color #1) in the tool window Pattern Colors / Yarn Colors.

main color in use (e.g. yarn color #1) in the tool window Pattern Colors / Yarn Colors. - The

icon appears beside the

icon appears beside the  symbol.

symbol. - Click the

icon.

icon. - The input panel for the sub-color appears.

- Click on the

icon.

icon. - A new empty sub-color will be created and selected.

- If required:

Call up the Change Color Value... context menu in order to change the color.

- or -

Delete the sub-color by Delete Sub-Color. - If required, create additional sub-colors for the same main color.

- or –

Switch to another main color in order to add sub-colors. - Select sub-color und draw it into the area of

Design Pattern for which different specifications are necessary.

Design Pattern for which different specifications are necessary. - The sub-color will be marked by the

icon and appears in the color parameter table.

icon and appears in the color parameter table. - Allocate the Float, Lock, Fabric selvedge module to the sub-color 1/1.

|

Modified Design Pattern |

Yarn Carrier View |

|

|

|

|

| |

|

| |

- 11

-

Start Technical Processing:

Start Technical Processing:

-

Show symbol view after technical processing.

Show symbol view after technical processing.

- 12

- Generate

Sintral.

Sintral. - 13

-

Start Sintral Check

Start Sintral Check - 14

-

Extract knitting program.

Extract knitting program. - A program for the knitting machine will be created: CMS530.Pattern-2.zip.

- 15

- Load knitting program into the machine.

: The extracted file CMS530W.Pattern-2.zip can be loaded onto the machine with an USB stick or via Ethernet.

: The extracted file CMS530W.Pattern-2.zip can be loaded onto the machine with an USB stick or via Ethernet.