Step by Step to Pattern-9 without Shape

Multi gauge knitting technique

This knitting technique is based on the intarsia knitting technique as the neighboring areas (coarse - fine) in one knitting row are knitted with different yarn carriers.

Machines with the multi gauges (mg) E1,5.2 to E10.2 are used, in order to achieve fabrics of high quality.

: Using Intarsia yarn carriers is recommended.

: Using Intarsia yarn carriers is recommended.

|

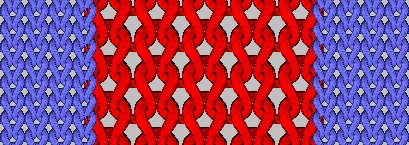

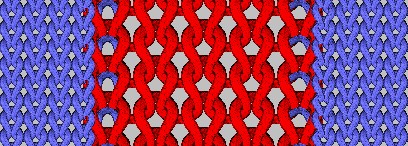

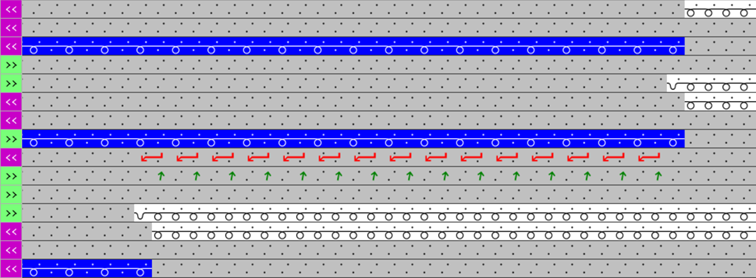

Stitch presentation before technical processing |

Stitch line before technical processing |

|

|

|

|

|

|

| |

|

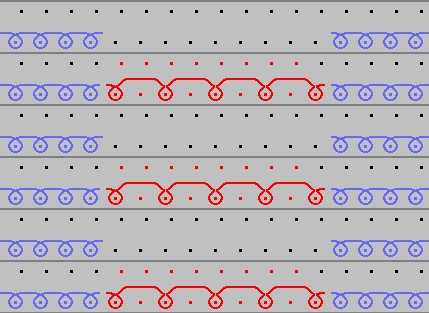

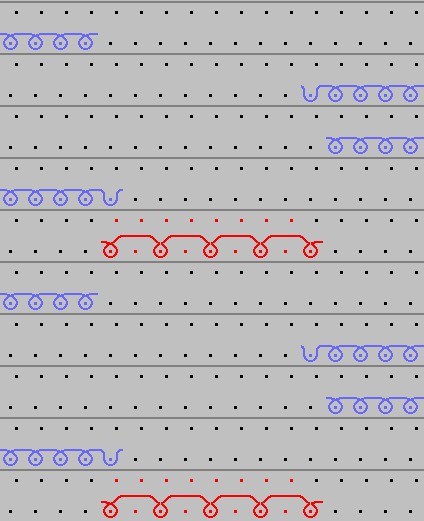

Stitch presentation after technical processing |

Stitch line after technical processing |

|

|

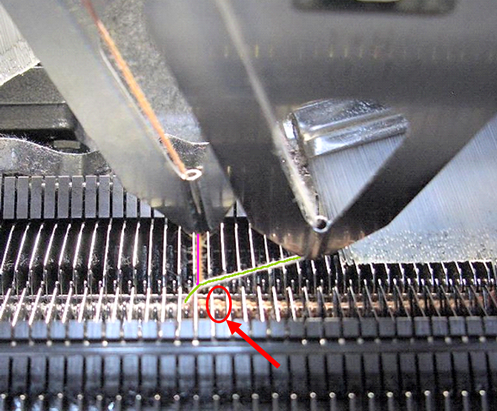

Intarsia binding at the border of the color areas:

|

|

Transition for the area from mg fine to mg coarse |

|

mg Transition, fine to coarse |

|

|

|

Transitions for the area from mg coarse to mg fine |

|

mg, Pick-up, Split coarse |

|

Recommendation:

|

|

|

|

mg, Pick-up, Stitch Fine |

|

|

|

|

|

mg, Pick-up, Stitch Fine, Transfer |

|

|

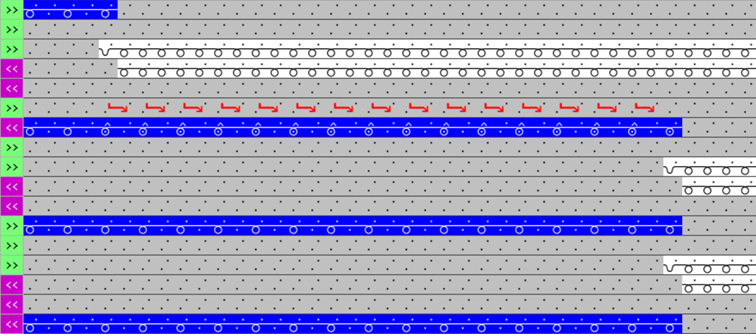

Step by step to Pattern-9 without shape:

- A pattern project with one pattern and the desired settings is created.

- 1

- Select any desired drawing tool under the Drawing group.

- 2

- In the Pattern Colors tool window, select the desired pattern colors from the Yarn Colors color palette to draw the motif:

- Yarn Colors:

-

: The yarn carriers are not automatically placed on the yarn carrier rails.

: The yarn carriers are not automatically placed on the yarn carrier rails.

The yarn carrier home position is determined in the Technical Processing.

- 3

- Draw the desired motif in the

Design Pattern with knitting elements from the Knitting Element Depot of the

Design Pattern with knitting elements from the Knitting Element Depot of the  Knit Explorer:

Knit Explorer:

- Directory Structure Modules / multi gauge coarse

- Directory Pattern Elements / Pattern Elements, multi gauge coarse

|

Example | |

|

|

Pattern neckline

For the yarn color #1 (white) there is a table entry in the Color Parameters table. |

|

| |

|

|

|

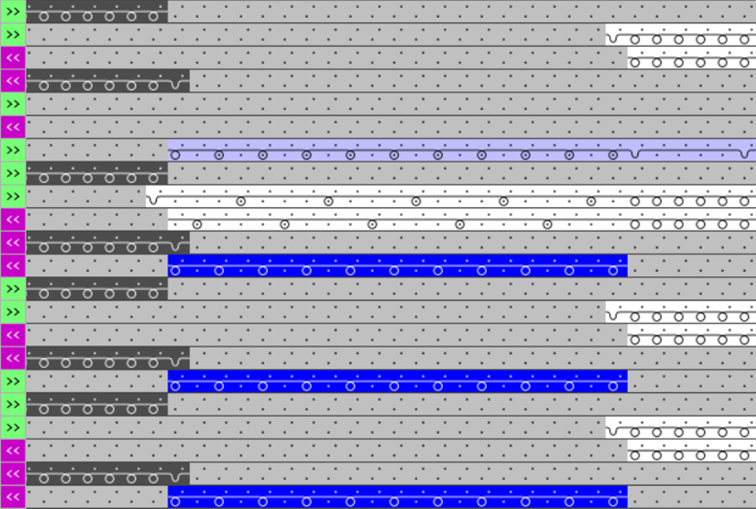

- 4

- In the

Design Pattern adjust the motif for the specifications with Yarn Carriersaccordingly, if desired.

Design Pattern adjust the motif for the specifications with Yarn Carriersaccordingly, if desired. - 5

- Carry out

Technical

Processing if necessary.

Technical

Processing if necessary. : After carrying out the

: After carrying out the  Technical

Processing you are able to view and weigh up the result of the automatic processing, if corrections / optimizations are necessary.

Technical

Processing you are able to view and weigh up the result of the automatic processing, if corrections / optimizations are necessary. - 6

- Back to the

Design Pattern to make pattern-related changes.

Design Pattern to make pattern-related changes. - 7

- Open the Yarn Carriers tool window for this purpose.

- 8

- In the Color Parameters table make the desired changes in the following groups, if necessary:

- Knitting-in and Out

- Intarsia Binding

- Border Processing

-

Allowed Stepping of coarse multi gauge rows

Allowed Stepping of coarse multi gauge rows -

Module for border processing, transition mg coarse to mg fine

Module for border processing, transition mg coarse to mg fine

- 9

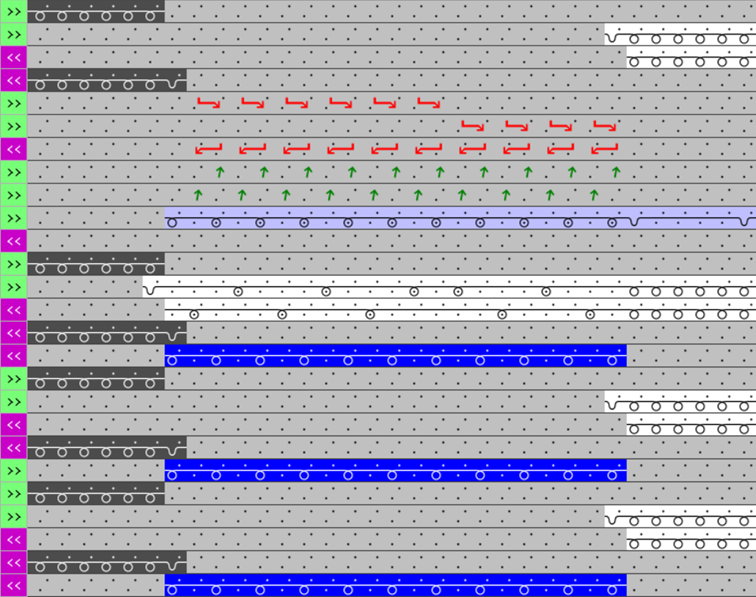

- If desired, make the desired presets in the following control columns:

- Stitch Length (NP)

- Main Take-down (WMF)

- Speed (MSEC)

- 10

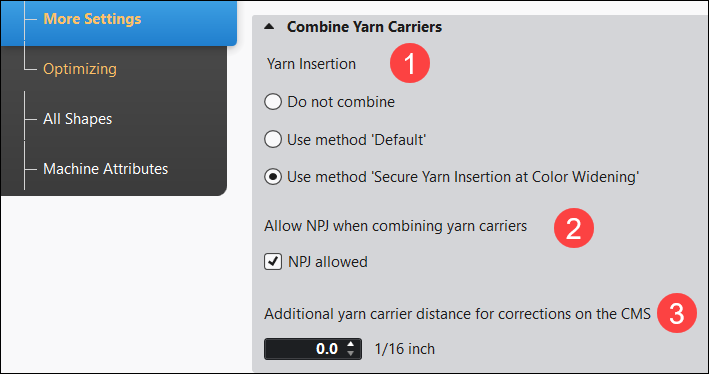

- If necessary, make the desired presets for combining yarn carriers in the More Settings tab of the Configuration dialog box.

Several yarn carriers are combined in one system by the technical processing (knitting sequence) to optimize the production time.

:

:

The yarn carriers will be combined only if this is possible based on the color field distances.

The result is visible in the  Symbol View after the technical processing.

Symbol View after the technical processing.

Options in the Configuration dialog box

- 1

- In the ribbon select the

Configuration button.

Configuration button. - The dialog box appears.

- 2

- Select the More Settings tab.

- 3

- Make the desired presettings for the Combine Yarn Carriers.

-

Yarn Insertion:

Secure Yarn Insertion at Color Widening is active (standard)

Secure Yarn Insertion at Color Widening is active (standard)

|

| ||||

|

1 |

Yarn Insertion | |||

|

|

Do not combine (Default setting) | |||

|

No automatic combining of the yarn carriers.

| ||||

|

|

Default | |||

|

Automatic combining of the yarn carriers, where the result cannot be influenced.

| ||||

|

|

Secure Yarn Insertion at Color Widening | |||

|

Automatic, uniform combining of the yarn carriers with an optimized knitting process for secure yarn insertion with the tuck binding.

| ||||

|

2 |

Allow NPJ when combining yarn carriers | |||

|

|

NPJ allowed (default setting)

Result: | |||

|

|

NPJ allowed is disabled

Result: | |||

|

3 |

Additional yarn carrier distance for corrections on the machine (YC/YCI) | |||

|

|

Adjust the safety distance in order to make corrections on the machine (YC/YCI in the setup).

| |||

- 11

- Start the

Technical

Processing.

Technical

Processing.

With the button, show .

button, show . - The yarn carriers are automatically combined after the set specifications and the Intarsia rules (constructive facts of the Intarsia yarn carriers on the machine).

- 12

- Generate

Sintral.

Sintral. - 13

- Start the

Sintral Check.

Sintral Check. - 14

-

Extract the knitting program.

Extract the knitting program. - A program for the knitting machine will be created: CMS530.Pattern-9.zip

- 15

- Load knitting program into the machine.

: The extracted file CMS530.Pattern-9.zip can be loaded onto the machine with an USB stick or via Ethernet.

: The extracted file CMS530.Pattern-9.zip can be loaded onto the machine with an USB stick or via Ethernet.