General information on EFS programming

Requirements for a communication between CMS and EFS 820/920:

- Existing power supply unit with Memminger cabling of the EFS.

- The Stoll EFS kit is installed

- The EFS are operated with Memminger EFS 820/920 firmware version 1.44 or higher

- Set the adjustable parameters in the Memminger setup of the EFS device to Default Parameters, see EFS operating instructions.

Original operating instructions EFS 920

Please, pay attention to the adjustable parameters in the setup menu of the original operating instructions of Memminger IRO

- The following parameters must be set at the EFS device:

- 1

- Permanent restore function Off Parameter Mode 12 = 0

- 2

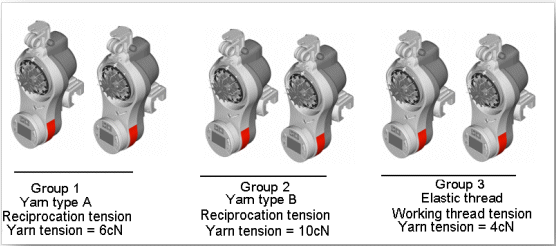

- Each EFS must be assigned to a group.

Parameter Mode 1 = 1 - 6 for the corresponding group.

If only one group is needed, it is defined with 1.

Restrictions

Up to 6 groups with different values in each knitting row can be served.

- As far as possible use the latest Stoll operating system for the machine.

The functionality is available starting with the operating system: V 5.0 (V_OKC_002.009.006_STOLL)

Actuation of the EFS 820/920 with the Sintral command DEVOUT

Sintral command syntax:

DEVOUT(1,2,3,4,5,6,7,8);

Restrictions

A maximum of 16 DEVOUT commands per carriage stroke can be processed.

The following commands can be transferred to the EFS devices via the DEVOUT command:

-

Initializing:

Initialization must be carried-out once in the Sintral before START via DEVOUT.

The program start must be carried out with SP1.

- Calibration:

The devices are to be calibrated once within each fabric piece. The calibration is carried out in one row, where the EFS is not used (e.g. comb course = - = or draw thread...).

When calibrating, the yarn is briefly lifted by the sensor so that it can calibrate again to 0. In case knitting takes place in this moment, the yarn might break.

-

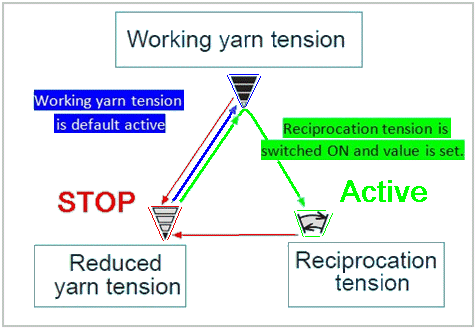

Selection of the working mode setting up the corresponding yarn tension:

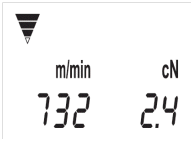

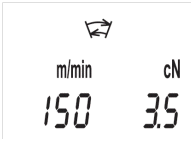

The current operating mode, and working thread tension, yarn tension reduction or reciprocation tension will be displayed on the device during the knitting process. Additionally the current yarn speed is displayed in m/min and the yarn tension in cN.

|

Working yarn tension | Yarn tension reduction | Reciprocation Tension |

|---|---|---|

|

|

|

The working yarn tension mode is the default mode. Without Sintral specifications, the EFS devices work with this mode. With flat knitting machines, this mode can only be used with elastic yarns. | When the machine stops, the EFS devices switch to yarn tension reduction. Normally, with flat knitting machines, the yarn tension reduction must be adjusted somewhat higher than the working thread tension or the reciprocation tension. | The reciprocation tension was developed specifically for flat knitting machines to return the yarn at the reversion. (Functioning principle Yarn return spring) The reciprocation tension is used for all non-elastic yarns. |

The yarn tension reduction may not have the same cN value as the working yarn tension.

With the same values, instead of the symbol for yarn tension reduction, the symbol for working yarn tension is displayed with the machine stop.

The yarn tension reduction must be activated once in the pattern. Afterwards the values can be changed in each carriage stroke.

The reciprocation tension must be activated each time, when a value is to be changed.