Creating patterns controlling the cast-off function via RS17

Create a new pattern:

- 1

- Select / from the menu bar.

- or -

Click .

. - 2

- Enter a Pattern name.

- 3

- Select the machine type and the desired setup type.

- 4

- Select Basic pattern (pattern without shape) and .

- 5

- Set pattern size and select the Front stitch with transfer basic knitting mode.

- 6

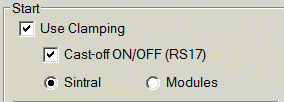

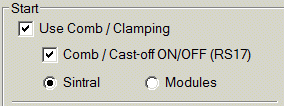

- Select start considering the cast-off function via RS17:

- Use Clamping

- Cast-off ON/OFF (RS17)

- Sintral

|

Machine with comb |

Machine with belt take-down | |

|---|---|---|

|

|

| |

|

|

The clamps are deactivated, i.e. the yarn carriers can not be brought into the clamp.

| |

|

|

Machine works with clamping and cutting.

| |

|

|

Each piece is cast-off as no control is performed via RS17. All yarn carriers must be in the clamp at the end of the fabric. | |

|

|

Cast-off can be controlled with the RS17. (Cast-off ON: RS17=0 /Cast-off OFF RS17=1) With the help of a Sintral instruction the piece counter is queried and with ST= 0 the RS17 is set to 0. This way all yarn carriers will be clamped and the fabric will be cast-off. | |

|

|

With a Sintral function, the start width of the new fabric piece is enabled through widening or casting-off. This selection is necessary with fully fashioned fabric. In case of fabric without shape this selection is also possible. | |

|

|

Only to be used with constant fabric width.

| |

- 7

- Select the start from Stoll with protection yarn / Standard / 1 System / without elastic thread / Transition loose row / Tubular.

- 8

- Confirm the settings with Generate Design Pattern.

- The Symbol view [Basic] will be opened.

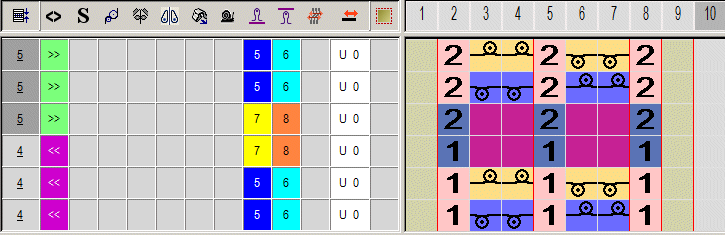

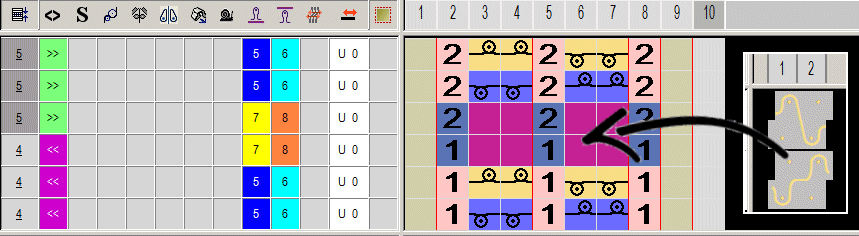

Settings in Configuration:

- 1

- In the menu call up the Configuration dialog box.

- 2

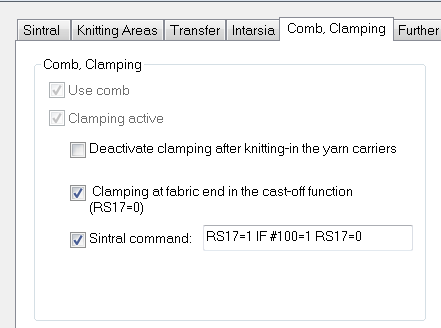

- Open the Comb, Clamping tab.

- 3

- Under the Comb, Clamping section, the following functions are automatically selected, if Cast-off ON/OFF (RS17) was selected with the start.

|

|

If RS17=0, all yarn carriers are clamped at the fabric end before casting-off the fabric. If RS17=1, the clamping of the yarn carriers is skipped. |

|

|

Via the Sintral command RS17=1 IF #100=1 RS17=0 casting-off is coupled to the piece counter. |

- 4

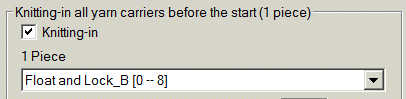

- In case of machines with belt take-down, knitting-in Float and Lock_B [8-8] is automatically adjusted for CMS530 HP B.

In the example, however, is used only clamping and cutting on the right side. Therefore, Float and Lock_B [0-8] was adjusted.

- 5

- Confirm the settings with the OK button.

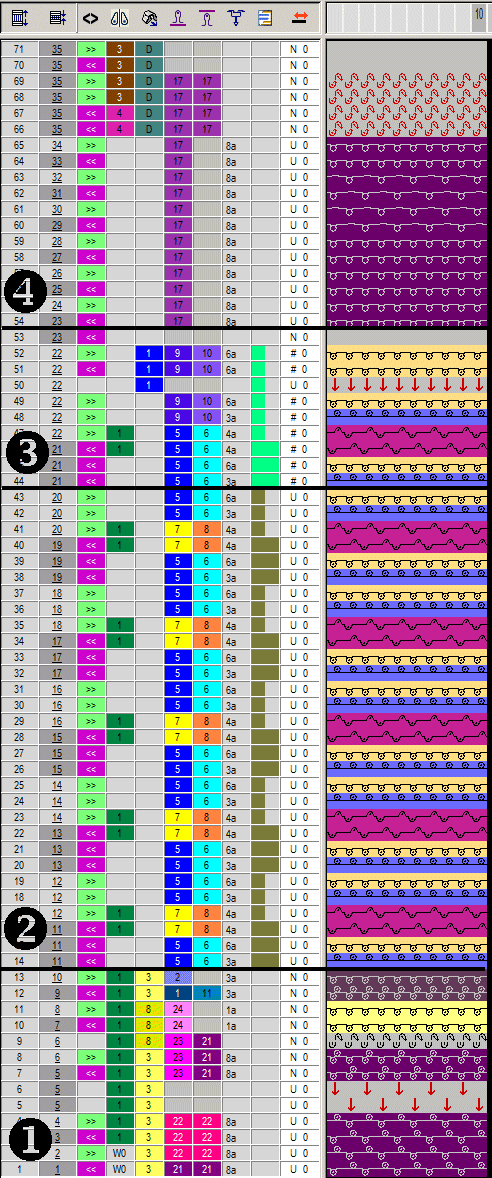

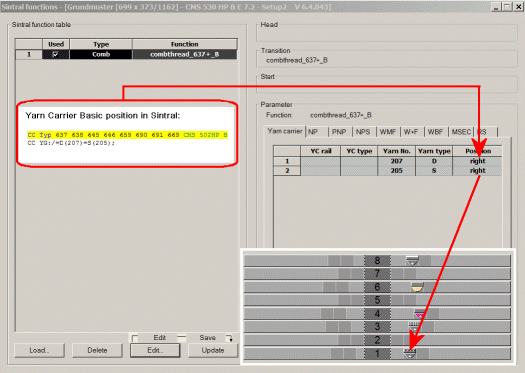

Call up Sintral function table:

- 1

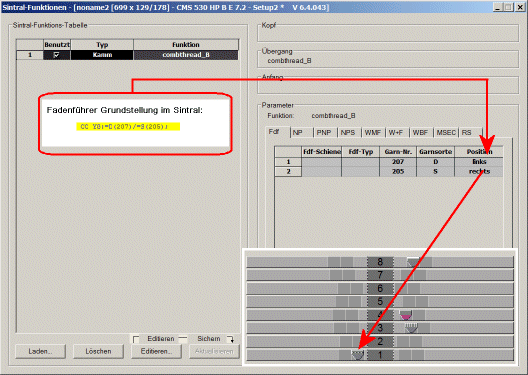

- The default Sintral function is automatically used for the CMS530HP_B: combthread_B.sin. With this Sintral function, the yarn carrier home position for the draw thread is on the left on track 1 and for picking-up after pressing-off on the right on track 8

Call up and allocation of Sintral functions:

- 2

- For all the following example patterns, the Sintral of a CMS502HP_B was used, where the draw thread is also on the right.

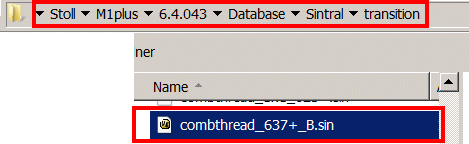

Please, delete the Sintral function combtread_B.sin and load the Sintral function combthread_637_B.sin:

Modify the Stoll start:

- 1

- Modify the inserted Stoll start.

- 2

- Via the / menu open the the Start directory.

- 3

- Open the Tubular technical container module double clicking.

- 4

- Open the Tub_1sys_without_E and delete all the knitting rows after the net row.

- 5

- Open the Tub_1sys_LR element and delete the knitting rows with rear stitch.

- 6

- Save the elements and replace the start.

Drawing the pattern:

- 1

- Create the basic pattern with the predefined basic module and knitting sequence.

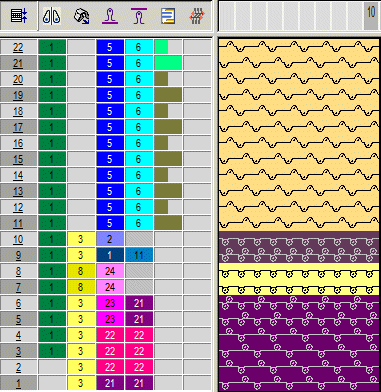

|

Basic module: |

|

The basic pattern is filled completely with this module. |

|

Knitting sequence pattern (CA) |

|

The knitting sequence is entered as CA over the entire pattern height |

|

|

|

In the CA, the reference rows (blue) have no needle action. The module from the basic pattern is inserted. |

|

Knitting sequence pattern end (CA) |

|

The last two rows of the pattern are overwritten with this CA. It enables secure transferring for the protection rows. |

|

|

|

|

|

Example basic pattern |

|

Drawing with basic module |

|

Processed Pattern |

|

(1

(2)

(3)

(4)

|

- 2

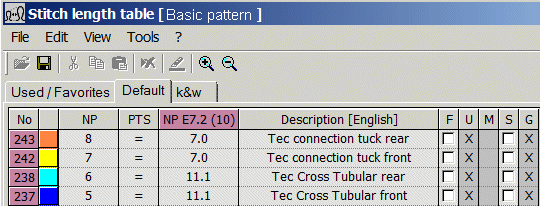

- Check settings for stitch length

There are private NP values for Tech Knits patterns:

- 3

- Check settings for fabric take-down.

For a machine with belt take-down with the E7.2 gauge, the take-down value WB=3-0 is sufficient. A higher take-down value can damage the belt permanently.

Complete the pattern:

- 1

- Switch to the tab and under activate

Use yarn color.

Use yarn color. - 2

- In the edit box beside it enter the color number of the protection yarn # 205.

The protection rows at the end of the fabric piece are knitted with protection yarn (residual yarn). - 3

- [not necessary, only if changes are needed after cutting-out shape] In the Steps of Processing

toolbar call up the .

toolbar call up the . - 4

- [not necessary, only if changes are needed after expanding] Expand the pattern with the

button of the Steps of Processing toolbar.

button of the Steps of Processing toolbar. - 5

- Start the technical processing with the

icon.

icon.

- The query appears.

- 6

- Confirm the query with OK.

- 7

- Call-up Sintral Check via the menu.

- or -

Click in the Steps of Processing toolbar.

toolbar.

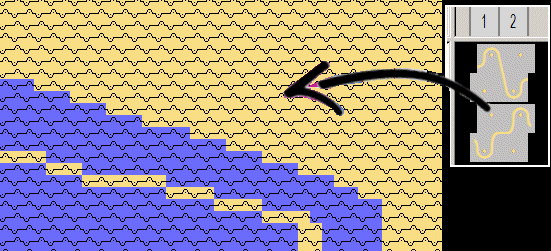

Use Clamping:

Use Clamping: Sintral:

Sintral: : The side selection of the comb thread and the draw thread can be freely selected in the yarn field.

: The side selection of the comb thread and the draw thread can be freely selected in the yarn field.