What was new in 6.8?

-

ESCI

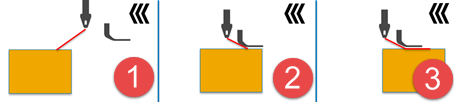

Correction values to control the shift points of weft yarn presser feet. - Example for weft yarn inlay with carriage direction to the left and start within the fabric

1 = Parking position

2 = Presser foot set down without correction

3 = Presser foot set down delayed by positive correction value

The carriage traveled an additional path since carriage return before the presser foot reaches the weft yarn. - You can specify the correction values of the individual indices in the Setup Editor.

Presser Foot - You can attribute the indices to the rows with presser foot by the control column.

Presser Foot Correction (ESCI) - ESCI 50 is exclusively reserved for corrections when changing the order of plating colors of inverse plating

W↓+/- = 7 nic

ESCI 50 is inserted automatically to prevent collisions of plating yarn carriers with the presser foot.

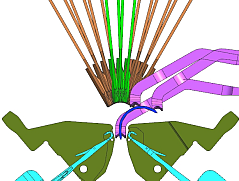

The technical processing replaces ESCI indices which you have inserted by ESCI 50. - Propose Rail Allocation for W machines (ADF-W + CMS-W)

You can prefer inner yarn carrier tracks for inserting weft yarns.

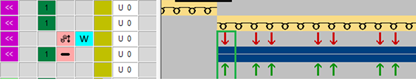

Propose Rail Allocation (dialog box) - Enclosing the weft yarn by transfer at the last needle as well

- Check box in Configuration / Further Settings.

The weft yarn will in any case be enclosed at the border of the color field.

Transferring at the last needle on the Configuration / Further Settings tab - The weft yarn cannot be withdrawn from the color field border when inserting the weft yarn in the opposite direction.

- Correction of stitch length groups NPGK

- Common items of a group of stitch lengths:

The group contains all the NP values of an individual area of the pattern.

With it, you can correct even different stitch lengths of this area in a quick and easy manner. - Setup Editor

NPGK (tab) - Stitch Lengths Pattern Parameters

Stitch length table - EKC machines previously starting with operating system EKC 1.4

--- FEHLENDER LINK --- - Search and Select

- Modified behavior of Search and Select

Intermediate results are not selected.

Only the final result appears as selection within the pattern. - Cascading search in intermediate results is no longer possible.

- Remedy:

Split the search list and run a second search within the resulting selection. - Multiple Search and Select

- Electronic Feed Wheels with EKC

- EKC machines starting with operating system EKC 1.3

- Was war neu in 6.7?

- New Machines

- ADF 530-24 B

- ADF 830-24 W

- The (Upgraded) flag shows the upgrade from OKC to EKC

Not sunken tuck for machines with converted knitting systems

Tuck bindings in gore areas can be knit tighter by not sunken tuck.

Therefore you have to convert individual knitting systems.

- You configure the converted knitting systems for your own machines with a system distance of 5".

System functions tab - You configure the usage within the whole pattern by the Configuration dialog box.

Each Tuck needle action gets to not sunken tuck with it.

Additional settings tab - You configure the usage within individual rows by the System Function control column.

Each Tuck needle action within this row gets to not sunken tuck with it.

System Function