What was new in 6.9?

This M1plus software version: 6.9

M1plus V6.9 is compatible with Machine operating system EKC 1.3

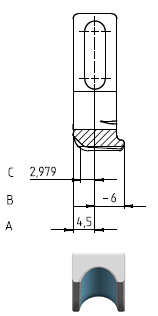

Different Types of Presser Feet

- Presser Feet tab in the Pattern Parameter / Machine Attributes dialog box and in the Machine Explorer.

- All types of presser feet available for the machine type are listed and can be assigned to each presser feet location.

- Presser Foot tab

- Attention:

Default with new pattern: Type 2 is allocated.

Check the equipment of the machine by the list and correct settings accordingly. - Enter this type of presser feet in to the control column of the pattern or the CA.

- The technology processing checks whether the entered type exists in the machine attributes.

An error message appears if not.

- Knitting-in presser foot function is available on ADF machines only.

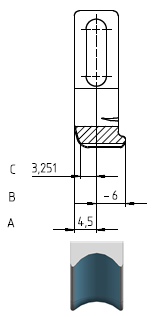

Presser foot with different geometrical forms:

| Type 1 | Type 2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

Series | All W-machines up to 05/2018

| All W-machines starting with 05/2018 | |||||||

Gauge | Needle bed gap | A | B | C | ID | Width | ID | Width | Entry Cams |

E18 | 1.25 | 4.5 | -6.0 | 3.0 | 268 381 | 1.1 | 273 761 | 1.1 | A |

E18m.16 | 1.25 | 4.5 | -6.0 | 3.0 | 268 381 | 1.1 | 273 761 | 1.1 | A |

E16 | 1.25 | 4.5 | -6.0 | 3.0 | 268 381 | 1.1 | 273 761 | 1.1 | A |

E8.2 | 1.55 | 4.5 | -6.0 | 3.0 | 269 124 | 1.4 | 275 160 | 1.4 | A |

E14 | 1.76 | 4.5 | -6.0 | 3.0 | 267 946 | 1.6 | 273 760 | 1.6 | A |

E14/12 | 1.76 | 4.5 | -6.0 | 3.0 | 267 946 | 1.6 | 273 760 | 1.6 | A |

E12 | 1.99 | 4.5 | -6.0 | 3.0 | 268 382 | 1.8 | 275 161 | 1.8 | A |

E12m.10 | 1.99 | 4.5 | -6.0 | 3.0 | 268 382 | 1.8 | 275 161 | 1.8 | A |

7.2 MG | 2.22 | 4.5 | -6.0 | 3.0 | 268 384 | 2.0 | 274 790 | 2.1 | A |

6.2MG | 2.30 | 4.5 | -6.0 | 3.0 | 268 384 | 2.0 | 274 790 | 2.1 | A |

E10 | 2.30 | 4.5 | -6.0 | 3.0 | 268 384 | 2.0 | 274 790 | 2.1 | A |

E14 (TT) | 2.30 | 4.5 | -6.0 | 3.0 | 268 384 | 2.0 | 274 790 | 2.1 | A |

E14/12 (TT) | 2.30 | 4.5 | -6.0 | 3.0 | 268 384 | 2.0 | 274 790 | 2.1 | A |

E12m.10 (TT) | 2.30 | 4.5 | -6.0 | 3.0 | 268 384 | 2.0 | 274 790 | 2.1 | A |

7.2 KW (TT) | 3.05 | 4.5 | -6.0 | 3.0 | 268 628 | 2.2 | 274 789 | 2.8 | B |

7.2 KW | 3.15 | 4.5 | -6.0 | 3.0 | 268 628 | 2.2 | 274 789 | 2.8 | B |

New entry cams for Type 2 of presser feet.

- The previous stitch tensions of lower NP values can not be reached anymore.

- Already formed stitches will get post loop sinking by the the modified cam curve.

Position | At the Left | Center | At the Right |

Quantity | 2 | 4 | 2 |

A | 274 008 | 274 010 | 274 009 |

B for E7.2 KW (TT) + E7.2 KW | 274 011 | 274 013 | 274 012 |

Take-down functions of belt take-down and fabric take-down

Preparing a change of the machine you can apply the allocated indices of the take-down.

- From a machine with main and auxiliary take-down (WMF) to a machine with belt take-down (WBF)

- From a machine with belt take-down (WMF) to a machine with main and auxiliary take-down (WBF)

- / menu

Convert Take-down Values

Two new key combinations:

- Auxiliary take-down table

Ctrl + Shift + A - Belt take-down table

Ctrl + Shift: + B - Key combinations (M1plus main program)

- The last set path is no longer stored globally but for the own machine in use.

- The check box is no longer available for machines with the EKC operating system.

- Context menu (My machines)

- The check box is no longer available for machines with the EKC operating system.

- Machines with the EKC operating system do not support order files (*.ord) !

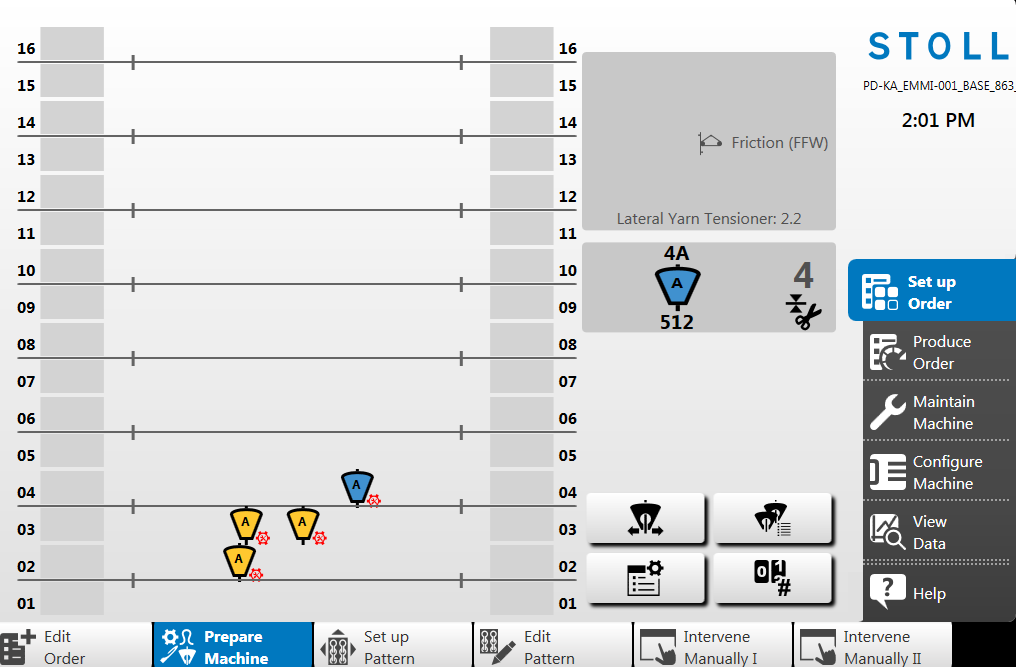

Order

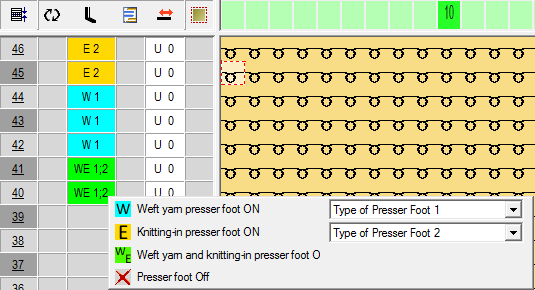

Better overview of the weft yarn carriers in the table of plating colors:

- Weft yarn carrier (ADF running before system 1)

Furthermore type Q - Weft yarn carrier by the leading system (normal yarn carrier)

for all CMS W machines

Type changed from Q to Qs.

Existing patterns for CMS 330 W or CMS 530 W will be converted automatically to Qs.

Inverse Plating by CA

As with ikat plating, you can also determine the expanding of the technical rows for inverse plating by a CA.

The difference:

ii marking in the plating colors for the ikat plating

Example:

- Plating color 1 and 2 for ikat plating

- Plating color 3 and 4 for inverse plating

After Technical Processing:

Both Net Jacquard modules Net 1x3 are also available for adapted quantity of colors (yarn bridges).

- Jacquard modules

- Net 1x3"

- Net 1x3, Restricted Float

- For the Jacquard variants in the No. of colors section

continuously similar

continuously similar minimum per row

minimum per row suited (yarn bridges)

suited (yarn bridges)

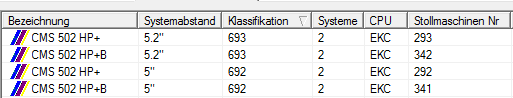

New CMS 502 machine with 50“ needle bed

CMS 502 HP+ with belt take-down or main take-down

You control the usage individually for the front and rear needle bed by the System Function control column

| Use the Tuck needle action as in the front needle bed only. |

| Use the Tuck needle action as in the rear needle bed only. |

| Use the Tuck needle action as in the rear needle bed only. |

: Need to modify the cam box!

: Need to modify the cam box!

New Float and Lock modules for belt take-down

| ||

|

| |

| Float and Lock Y-CR0_B_2Y [0 -- 16] | |

Float and Lock Y-CR0_B_2Y [16 -- 16] | ||

Float and Lock_B_2Y [0 -- 16] | ||

Float and Lock_B_2Y [0 -- 8] | ||

Float and Lock_B_2Y [16 -- 16] | ||

Float and Lock_B_2Y [8 -- 8] | ||

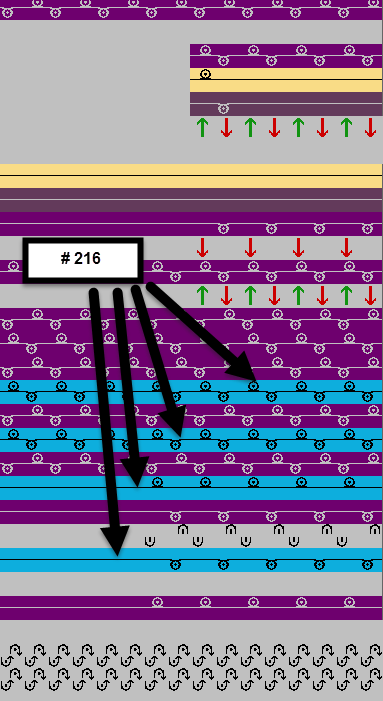

With technical yarn #216 protection yarn_B_2Y for a second yarn carrier

New Float and Lock modules for k&w

2x16 clamping positions for ADF 32

| |||

|

| ||

|

| k&w Float and Lock [16 -- 16] | |

| |||

|

| ||

|

| k&w Float and Lock 2 Pieces [16 -- 16] | |

Knitting Time, Yarn Carrier Allocation and Yarn in Report (*.cfgx)

Report (cfgx file) contains data relevant for production as machine, run time of the fabric piece and yarn consumption.

starting with version 1.6

starting with version 1.6

The calculated knitting time in the cfgx file forms the basis for production planning

- Specifications of the respective yarn carrier

Dimensioned shapes of GKS V. 2.3 are supported.